PRODUCTION MACHINING

PRODUCTION MACHINING

Where Precision, Efficiency, and Craftsmanship Meet

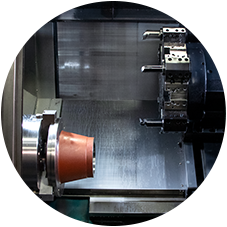

EK is home to 17 CNC machining and turning centers that accommodate a large range of materials and component sizes. Our adaptable and skilled team of manufacturers complete a series of quality assurance measures for each project to ensure every component and assembly that leaves our line meets or exceeds expectations.

Advanced In-House Production of Large-Scale and Complex Weldments

EK’s capabilities span beyond general machining to include in-house tight tolerance weldments. Our state-of-the-art equipment and experienced manufacturers are well-versed in:

- Bearing alignment requirements

- Specific surface finishes for bearing retainers

- Tight tolerance mounting holes

- Precise alignment of components

By providing tight tolerance machined weldment services in-house, our team can effectively reduce lead times to completion by eliminating out-sourcing, scheduling each process internally, as well as eliminating the costs associated with outsourcing. Work with EK to eliminate budget and production waste by taking advantage of our one-stop shop for complete manufacturing.

Eliminating Production Downtime

Our multiple pallet, high-speed horizontal machining centers are specially designed to perform numerous operations using the same set-up which helps to eliminate unnecessary load and unload time, making continuous operation possible. Our turning centers are also equipped with automatic bar feed systems for nonstop production runs from 25 to 25,000 pieces. To truly boost production, our machines are equipped with high-pressure coolant to utilize the most productive tooling available. Our production processes are calibrated and tested to optimized efficiency and quality to deliver components and assemblies on time and on budget.

Diverse Material Capabilities

Our team of manufacturing experts has vast experience working with various carbon, tool, and stainless steels, as well as castings, forgings, weldments, aluminum, brass, bronze, plastics, and powdered metals.

Available Materials:

- Aluminum

- Brass

- Bronze

- Castings

- Forgings

- Weldments

- Plastics

- Powdered Metals

Production Machining Capabilities

Turning Centers

Adaptable, state-of-the-art CNC turning for effective subtractive manufacturing.

Machining Centers

Efficient, automatic tool change overs for complex metal machining and die manufacture

5 Axis Machining

Two rotational axes combine with three conventional axes to enable machining of even more complex shapes